The wheat-harvest season is here again, and memories of the threshing ground return to my mind. When I was four or five, my memory was hazy—I remember that back then tractors were still rare. After harvesting the wheat in the fields near the lake, binding the sheaves, they were carted back and spread out to dry on the threshing floor. Once sufficiently dry, it was the turn of the little donkey. The little donkey would drag a stone roller around and around the yard, countless laps, until the grain was pressed down. Next door, a woman’s green mule was even stronger than our little donkey.

Sometime when I was in elementary school, tractors began to spread slowly. My family’s first purchase was an eight-horsepower walk-behind tractor. With that, life became lighter, and the little donkey was eventually sold. With the arrival of tractors came the reaper—though back then the reaper only harvested; it merely replaced the sickle. My family didn’t own one; we hired people to harvest, lining up and paying by the mu—I don’t recall how much per acre. After the wheat was cut, the tractor hauled it home. I remember one year when Dad was driving back and swerved to avoid a little girl riding a tricycle—he ended up crashing into a roadside ditch and dumped the entire load of wheat. Thankfully, he himself was unharmed.

Even with tractors, the threshing process remained. But now, dragging the stone roller, it wasn’t the little donkey doing the work—but the tractor. When threshing began, every tractor in the village seemed to turn out. They circled tirelessly, exhausts belching black smoke, steam rising from radiators. Pah—pah—pah… the noise never stopped. The wheat-harvest season in my childhood was the noisiest time. The whole village droned from dawn to dusk in the racket of tractors. It wore on the listeners, and even the tractor drivers—heads spinning from the constant motion and noise.

That sound—whether the stone roller scraping or the tractor’s roar—I wish I could hear it again. After lap upon lap of rolling, the wheat grain would fall, and the stalks crushed. Then came the next task: piling the straw, and gathering the grain. Crushed straw was the best fuel; in my hometown, we called it maojiang. It burned hot—fired meals year-round. What should we do with all that straw? We piled it up. Building straw piles was my favorite job. Compared to other harvest tasks, it was far more fun and less tedious.

When building straw piles, our whole family pitched in—young and old alike—each wielding a pitchfork, stacking straw. My father, fond of me, always let me stand on top and stomp it down. That compacted the stack and helped shape it into a high, good-looking pile. Even as a child, I stomped and stomped. When we built a stack, neighborhood kids often competed to stomp there—sometimes two or three kids bounced atop the pile together. After the wheat harvest ended, each family’s threshing ground looked like a mountain range of straw stacks. Sometimes it wouldn’t be used up for a whole year.

By the way, maojiang wasn’t just for fuel—it was also used when burning joss paper for ancestors during festivals. You’d bring some straw along to add to the fire, and it was as valuable as paper money. Elders said that if straw is burned for the ancestors, they receive gold ingots in return. The straw stacks are rare now—so when burning offerings, there’s only paper joss money. I wonder if our ancestors miss the gold ingots—probably not!

Once the straw stacks were piled, the threshing ground looked clear—just stacks of grain remained. At that point, the grain was full of chaff, bits of soil clods, husks, and broken straw. Clearing those was laborious. During the day, the grains spread to dry, and every hour or two, someone had to turn them so the lower layers also received sunlight. In evenings, we’d gather the grain into mounds again to shield against dew or sudden nighttime rain. Gathering also helped when clearing impurities. This job was called “yang chang” (raising the grains)—using wooden shovels to toss the grains into the air, letting the breeze blow away husks and stray chaff.

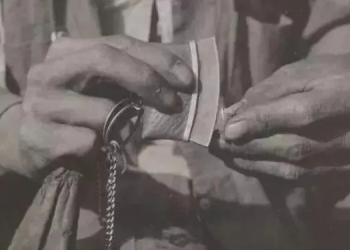

But the wind must be just right—not so weak the impurities don’t separate, not so strong that the grains blow away. Later came the mechanical winnowing fan—a tool resembling a vertical oscillating fan that let you winnow grain regardless of the wind. The busy scenes at the threshing ground were sometimes disrupted by sudden storms. In the 1980s and ‘90s, weather forecasts were unreliable. In rural areas, summer afternoons often brought torrential rains. Every rural child lived through the scramble to protect the harvest. Often, a cloud would block the sun and rain would pour. If we couldn’t gather the grain in time, the loss could be devastating. Villagers were incredibly united—when our yard was done, we’d rush to help neighbors. Even so, some wheat would still get drenched.

Then came the threshing machine—no more rolling fields. You harvested and fed directly into the machine; it separated the grain from stalk and head. But the real relief came in the era of large-scale combine harvesters. When I entered high school, these machines became more common. Most were from outside villages and required queuing.

Now, every village has several. A combine heads straight into the field—a four or five-acre patch done in about an hour. The grain can be sold right by the road—no more hassle, no more dusty fields. The harvest ground became peaceful again post-combine era. Combine harvesters really were a great invention for farmers. They simplified the entire wheat-harvest process. No more dusty chaos, no roaring tractors, no worry about sudden storms. And though today life is easier, the old days still stir nostalgia. The sweat-drenched harvest scenes, the straw-stack playtime, even the little sting of wheat awns in my fingers—all remain beautiful parts of my life.