I, Zhao Dongwan, joined the revolution in 1938 at the age of 12. Over the years, I have worked and studied in various regions, departments, and units. However, the most unforgettable and vivid memories are from my 14 years at the Fulaerji Heavy Machinery Factory (hereafter referred to as “Yizhong”). Those years remain etched in my mind.

Upon hearing about this assignment, I felt both excited and somewhat confused. I had no idea what Fulaerji was like. I had never heard of it before and had never been there. Yet, knowing that the organization that had trained me had made this decision, I believed there must be a valid reason behind it. I could not question it, so I happily accepted the assignment and vowed to carry out the tasks given to me.

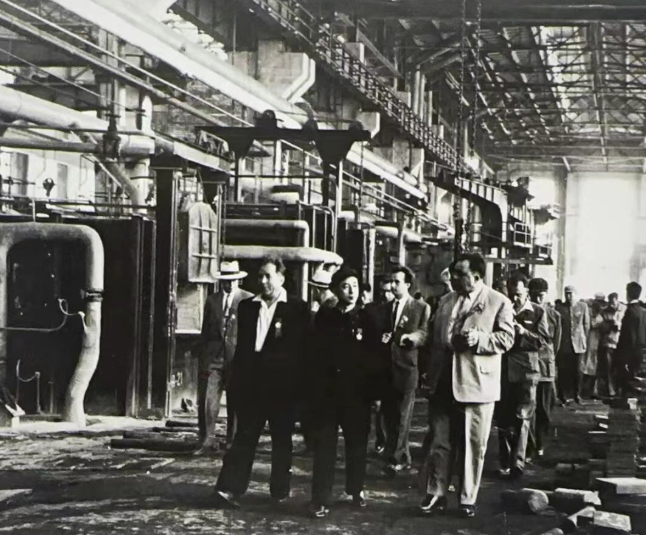

In September 1957, I reported to the Fulaerji First Heavy Machinery Factory and, from that moment on, joined the vast workforce at Yizhong in the exhilarating construction boom and the challenging preparations for production technology.

Originally, Fulaerji was a small fishing village inhabited by the Daur ethnic group, situated on the banks of the Nen River. It was a barren land, covered in wild grass, with wolves and wild dogs fighting among the weeds. Its existence could not be found in any history books, nor was it marked on any map—it was an uninhabited, desolate region.

The natural conditions here were harsh and unforgiving. The climate was bitterly cold, with strong winds that often made walking impossible. At times, the wind was so fierce that people had to crawl on all fours just to move forward. The temperature was often below -30°C, sometimes even plunging to -40°C. Despite these extreme conditions, the builders of Yizhong were undeterred. They faced the challenge head-on, marching forward with determination as they began constructing the factory.

The construction scale of Yizhong was grand, with 114 engineering projects. The factory occupied an area of 5.8 million square meters, with a total construction area of 630,000 square meters. The factory housed more than 6,000 pieces of equipment, with the largest workshop covering over 50,000 square meters. The highest building, the heat treatment workshop, stood at 40 meters, while the underground caisson project, with a depth of 26.5 meters, made the total height nearly 70 meters. The largest overhead crane had a lifting capacity of 300 tons. Fulaerji First Heavy Machinery Factory was the largest and most modern heavy machinery plant of the 1950s and is considered the largest modern heavy machinery factory in Asia.

During the construction, we encountered many challenges. The most difficult were three key engineering projects:

For any workshop with a crane capacity of over 75 tons, its foundation required piling. A total of 12,402 reinforced concrete foundation piles needed to be driven. These piles ranged from 12 to 16 meters in length, with a cross-section of 350×350 mm. During the piling process, we frequently encountered breakages and fractures, and progress was slow—only about 1,000 piles were driven in the first three months, severely delaying the construction schedule. After discussions with the construction team, we decided to send our deputy chief engineer, Zhang Shumei, to Moscow’s Soviet Heavy Machinery Design Institute to discuss solutions to the pile foundation design and, at the same time, to research the caisson project’s design and construction technology. After numerous on-site experiments and adjustments to tools and methods, the piling project gradually began to make progress.

The underground structure for the installation of shaft-type heat treatment furnaces required isolation from underground water. This structure, made of reinforced concrete, was 37.8 meters long, 21.3 meters wide, and extended 26.5 meters underground. It housed the heat treatment furnace and quenching oil tank, and it was crucial to prevent groundwater from infiltrating the structure. The project was technically complex. We brought together domestic and foreign experts to discuss construction plans, and after comparing several options, we decided to adopt the pneumatic caisson method for the construction. This method was chosen because it could ensure construction quality despite the high technical demands and the narrow construction site. Preparation for this included meticulous planning of equipment and materials, strict selection and training of workers, and performing soil pressure and settlement tests. Additionally, 18 temporary projects were built to ensure safety and quality. The caisson project was completed in just 88 days from the start of construction to the sealing of the bottom, marking the fastest and highest-quality project.

The construction of the factory building required over 62,000 tons of steel, most of which were used for the building’s steel framework. The primary challenge was the heavy, large, and high-quality components. For example, each steel column in the steel casting workshop weighed 82 tons and reached 38 meters in height, with steel plates up to 40 mm thick and base plates up to 80 mm thick. The large-scale metalworking workshop had a span of 36 meters. Due to limitations in lifting and transportation, we decided that each steel column would be fabricated in three sections and then transported to the construction site for assembly and welding during installation. This process significantly increased installation difficulty, especially the on-site welding of large components, which was unprecedented in domestic construction projects.

These three major projects were technically complex and posed significant challenges. However, through the joint efforts of both parties, we successfully overcame them, which laid a solid foundation for the early completion of the factory’s construction.

The construction workforce and leadership at Yizhong were composed of personnel drawn from across the country, with support from all directions. A group of county-level cadres from regions such as East China, North China, Central South, and Northeast China were assigned as the factory’s mid-level backbone. In addition, the Ministry of Machine Building and the Heilongjiang Provincial Party Committee tasked Yizhong with the responsibility of staffing the factory, bringing in more than 7,400 workers from Heilongjiang, Jilin, Liaoning, Jiangsu, Tianjin, Beijing, and other provinces during 1957 and 1958. During the factory construction, approximately 200 outstanding university graduates were assigned to Yizhong annually. The technical workforce was assembled from all parts of the country, with many of them having studied in the Soviet Union or the United States. The three deputy chief engineers were selected nationally, including Li Yizhang (who had studied in the U.S.), Zhang Shumei, and Feng Zipei, both of whom were selected from Beijing.

By the time the factory officially began production in 1960, the workforce had grown to over 16,000 people, forming a highly skilled technical team. The leadership at all levels took the construction of Yizhong very seriously, fully leveraging the advantage of “one unified strategy across the country.” This was the fundamental guarantee for the successful completion of the factory.

From the selection of the product plan to choosing the factory’s location, and from the major challenges in construction to the final stages, the leadership of the State Council was personally involved, with the Ministry of Machine Building and the Ministry of Construction co-leading the efforts. The Heilongjiang Provincial Party Committee and the Qiqihar Municipal Party Committee treated the construction of Yizhong as a top priority. In this way, the entire nation and province supported the project.

During the peak of construction, more than 25,000 workers participated, with the most advanced modern construction machinery available in China at the time. The supply of materials was handled with urgency, even drawing from the national steel reserves. Both imported and domestic equipment arrived by the end of 1959. To ensure quality and meet deadlines, we adopted a parallel construction approach, setting up three distinct lines—air, ground, and underground—within a single factory building. Each team had its specific task, and the entire construction site was a hive of activity, with machinery running constantly, 24 hours a day. The efficiency was stunning, and work plans were completed daily, bringing rapid changes to the site.

I firmly believe that any scientific or technological achievement must undergo repeated testing. The manufacturing of the large columns was no exception, and despite opposition from some quarters, I decided that we must conduct tests. The results of the simulation test completely matched the expected calculations from the design, and the initial success greatly encouraged everyone involved.

Next came the decision on the specific welding method to use. Driven by the noble sense of responsibility to complete the national task, both the technicians and workers engaged in repeated research, analysis, and comparison. In the end, we decided to adopt a method called melted nozzle electroslag welding, which combines wire electrode welding and plate electrode welding. For safety reasons, we decided to weld a total of five large columns, with one serving as a spare. The first column was welded smoothly, but during the welding of the second column, the first weld joint failed twice, forcing us to stop welding and cut it off with gas cutting for rework and welding again.

At that time, the entire group of Soviet experts, led by the factory’s chief expert Tarasov, collectively wrote to the factory director and me, urging us to stop the welding and halt production. After careful consideration, we decided not to adopt the “expert suggestion” and firmly replied that the welding work could not be stopped for even a day. I arrived at the welding site around 9:00 p.m. and addressed the team, saying, “The air can be inflated but must not leak. Since the first column was welded successfully, the second and third should be achievable as well. The welding work must continue without interruption.” I encouraged everyone to “cheer up, boost your morale, summarize our experiences, work together, take necessary measures, and continue our battle to complete the task on schedule.”

After more than 40 days of continuous effort, we successfully completed the welding of all five large columns by the end of March 1959, laying a solid foundation for the manufacturing of the 10,000-ton hydraulic press.

It’s worth noting that electroslag welding is a new method that can weld cross-sections of any size. It is relatively easy to operate, and the quality is highly reliable. When Synov, the chief designer from the Soviet Heavy Machinery Design Institute, visited the factory and saw the completed large columns, he remarked: “The Soviet Union is the birthplace of electroslag welding, but we have never welded such large components. You are truly remarkable, congratulations.”

In 1962, Professor Pan Jiying from Tsinghua University introduced our use of electroslag welding for large columns at the International Welding Year conference held in the Netherlands. The presentation received high praise from the delegates, who considered it a major event in the global welding community.

In 1944, Germany manufactured the world’s largest forging hydraulic press at 30,000 tons. By 1955, the United States had built two 31,500-ton and two 45,000-ton forging hydraulic presses. The Soviet Union built two 30,000-ton and two 70,000-ton forging hydraulic presses between 1959 and 1961. In 1967, the UK installed a 30,000-ton multi-directional forging hydraulic press, made in the United States. The construction of large forging hydraulic presses is, to a large extent, a reflection of a country’s technological level in scientific research, design, and manufacturing.

China’s ability to manufacture such large mechanical equipment was unprecedented and created quite a stir internationally. Designing and manufacturing a 30,000-ton forging hydraulic press was far more complex and challenging than a 12,500-ton press. At the time, we had no data on the 30,000-ton forging hydraulic press. On one hand, we organized technical personnel to collect relevant data, while on the other hand, I led a delegation to the Soviet Union for field research. By this time, Sino-Soviet relations had soured, and our visit was heavily restricted. Despite the extreme difficulties, we managed to gather limited technical data. Ultimately, we decided to start by manufacturing a model, and we built a 1:10 scale metal prototype to conduct structural, strength, and rigidity tests. Using data from 150 points, we were able to determine the appropriate dimensions for the overall structure and large columns of the 30,000-ton press. This was a crucial step and a key factor in the success or failure of our design. After the technicians’ hard work, the tests were successful, and we moved on to the design phase. In 1963, we completed the design and began production.

During the manufacturing process, I applied the experience we had gained from producing the 12,500-ton hydraulic press. We first gathered experts to analyze and research the manufacturing difficulties, then worked together to find solutions. After several rounds of analysis, we identified the following key issues to address:

The Upper Crossbeam: The casting weighed 167 tons, requiring 235 tons of steel. We adopted a multi-furnace smelting and casting method, which was successfully executed.

The Eight Large Columns: These were larger than those of the 12,500-ton press, but since we already had experience with the smaller columns, this part went relatively smoothly.

The Crossbeam: Weighing 135 tons, it was designed using specially thick plates. Since the country was unable to produce plates of such width, we forged the plates ourselves and processed them through welding. A total of 23 longitudinal plates were welded, with the dimensions of the welded piece being 11.65 meters long and 3.2 meters wide. The welding was successful on the first attempt, and the longitudinal plates ensured the quality of the product.

The Base Plates: For the 12,500-ton press, the base plate was forged from 140 tons of alloy steel. This large-tonnage, large-surface alloy steel forging was the first of its kind in the country.

The Bronze Sleeves in the Working Cylinder: There were 16 bronze sleeves, each requiring 3,500 kg of copper. The design specified that the lead content should be 20%. However, such a high lead content would inevitably cause significant lead segregation in the castings. We implemented numerous measures to successfully complete the task.

The Synchronization System for the 30,000-Ton Press: The synchronization system was designed to ensure that the movement of the crossbeam remained within a tilt of 0.15 mm per meter. These key challenges were all resolved.

The 30,000-ton press was gradually delivered. Due to the large size of the components, transportation was difficult, and the installation was delayed by the disruptions caused by the Cultural Revolution. The installation was finally completed in the early 1970s, and the press officially entered production. This was China’s only 30,000-ton forging hydraulic press.

Since its installation and production, the press has undergone over 30 years of testing, proving that the design of the equipment and its system structure are sound. It is superior to the equivalent Soviet presses, with reliable test data and excellent overall quality. In 1978, it was awarded a prize at the National Science Conference.

On February 6, 1980, the 1700mm continuous rolling mill, jointly designed and manufactured by China First Heavy Industries (formerly First Heavy Machinery Plant) and the Beijing Steel Design Institute of the Ministry of Metallurgy, was officially put into production at Benxi Steel.

This was China’s first domestically designed, manufactured, and installed wide-strip hot continuous rolling equipment, with construction beginning in 1974. The successful production of this rolling mill marked the end of China’s long-standing dependence on imported high-end hot rolling equipment. It became the only modern hot continuous rolling production line with independent intellectual property rights in the country during the 1980s. The project also laid the critical technical foundation for the domestic manufacturing of large rolling mills, such as the 1780mm mill at Anshan Steel and the 2050mm mill at Baoshan Steel.

Benxi Steel used this rolling mill to develop high-end products such as automotive sheets, oil pipeline steel (X80 grade), and container steel. The overall yield rate of the products improved from less than 85% in the early stages to 97.85%, while the annual production capacity increased from the design capacity of 1.5 million tons to 3.8 million tons. This transformation directly propelled Benxi Steel from mass production of ordinary steel to a high-quality steel plate base.

As the “only child of the Republic,” the technological breakthrough of this rolling mill set a benchmark for China’s heavy equipment manufacturing industry. Its model of independent innovation was included in the National Science and Technology Major Projects, and the related technological achievements have been applied to overseas projects, such as the 1800mm hot continuous rolling project for the Turkish TOSYALI Group, helping to promote China’s steel equipment “going global.”