Deyang, a city not widely known, is a key base for China’s heavy equipment manufacturing industry, producing 40% of the country’s water turbine generator sets. Established in 1958, Dongfang Electric is the most important core subsidiary of the state-owned China Dongfang Electric Corporation. It is a pivotal enterprise in China, specializing in the research, design, and manufacturing of large power generation equipment.

Based on the national energy strategy requirements, since the 1970s, Dongfang Electric has successively developed a series of hydropower generator sets for major national hydropower projects such as Gezhouba, Three Gorges, Xiluodu, Changlongshan, and Baihetan. By doing so, they have firmly mastered the core technologies. Every hydropower station that represents the highest domestic standards bears the imprint of Dongfang Electric; in China, one out of every four kilowatt-hours of electricity is generated by Dongfang Electric’s equipment. On May 16, 2023, Dongfang Electric once again made history: the company successfully rolled out the country’s first 150 MW large impact turbine, the largest single-unit capacity in China, marking a significant achievement in the domestication of key core technologies for high-head, large-capacity impact hydropower generator sets—turning a dream into reality. The impact hydropower generator is an essential model to support the national strategy to “accelerate the construction of the Southwest hydropower base.” With the self-developed 150 MW impact turbine, Dongfang Electric has taken a crucial step in the development of large impact hydropower generator sets, creating favorable conditions for the construction of the Southwest hydropower base and the development of rivers with significant elevation drops. Growing alongside the new China, Dongfang Electric has helped China’s hydropower technology transition from catching up, to keeping pace, and ultimately leading the way.

On the display rack of Dongfang Electric’s hydraulic test platform, seven impact turbine models, similar in appearance, are lined up side by side. These turbines stand out from more than 100 design proposals and mark the journey of domestic R&D for the 150 MW impact turbine. The impact turbine is the core component of the impact hydropower generator, designed for high-head hydropower stations. In terms of performance, it is the preferred model for hydropower development and construction in China’s southwestern plateau and canyon areas. The development of the impact turbine, the core component of the impact hydropower generator, has long been a “bottleneck” technology that restricted the development of China’s impact hydropower stations. Prior to Dongfang Electric’s independent development of the impact turbine, all impact hydropower stations in China used turbines purchased from foreign companies.

In 2018, Dongfang Electric’s R&D team received an experimental and factory acceptance report for the impact hydropower generator set from a foreign supplier to Sichuan Investment Group (referred to as “Sichuan Investment Group”). The report contained only a few basic technical parameters, with no key data. Dongfang Electric’s R&D team had no idea how the impact turbine had been manufactured and was left frustrated. Had it not been for the strategic cooperation agreement signed between Dongfang Electric Group and Sichuan Investment Group in 2019, deciding to jointly tackle the challenge of domesticating large impact turbines, Dongfang Electric’s R&D team would never have seen the foreign report. “We used to follow the technology introduction route, but now that’s no longer feasible,” said He Qiyuan, Deputy Director of Dongfang Electric’s R&D Center. “They can only sell you the product.” So, what could they do? The only option was to develop it independently.

In fact, Dongfang Electric had started preliminary planning and verification for the independent development of impact hydropower generators around 2012. Under the leadership of Liang Quanwei, Deputy General Manager and Chief Engineer of Dongfang Electric, the company assembled a 43-member R&D team, selecting the best experts from various professional fields. The team officially began developing the impact hydropower generator. It wasn’t until May 16, 2023, that Dongfang Electric successfully developed the country’s first 150 MW large impact turbine, with the largest single-unit capacity. He Qiyuan said, “The process was extremely challenging.”

To develop the impact-type hydropower generator, the first step was to build a testing platform. The hydraulic test platform is an important support for testing hydropower generator models, and the requirements for the platform are even higher for impact-type hydropower generators. In 2018, the R&D team began building the impact hydraulic test platform on their own, but the initial efforts were not successful. He Qiyuan and his team had only seen foreign test platforms before, and had no idea about the internal structure. They searched for information, tackled problems on their own, and eventually created the first water distribution ring pipe for the test platform. However, when they tried it, they discovered it was completely unusable. The first failure did not dampen their enthusiasm.

During this process of building the impact hydraulic test platform, Dongfang Electric was also making strides in its digital construction. He Qiyuan and Song Min, Deputy Director of the R&D Center, had an idea: could they leverage their digital construction experience to create an intelligent test platform? After team discussions, they decided it was feasible. After more than two years of constant exploration, testing, and optimization, a fully automated, unmanned test platform model was finally created. Unlike traditional tests that required models to reach a stable operating state before data could be recorded, the new platform could now be activated with the press of a button, with features like jet control and data sampling fully automated.

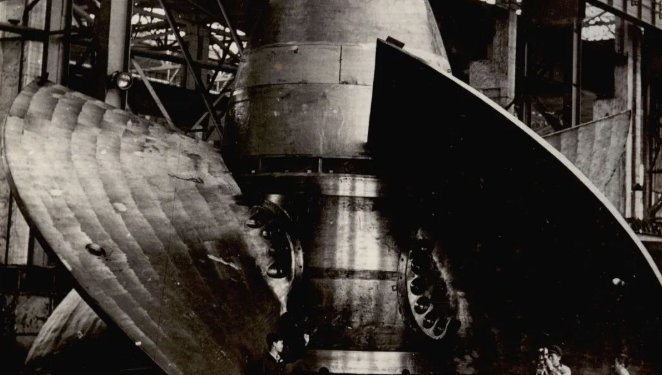

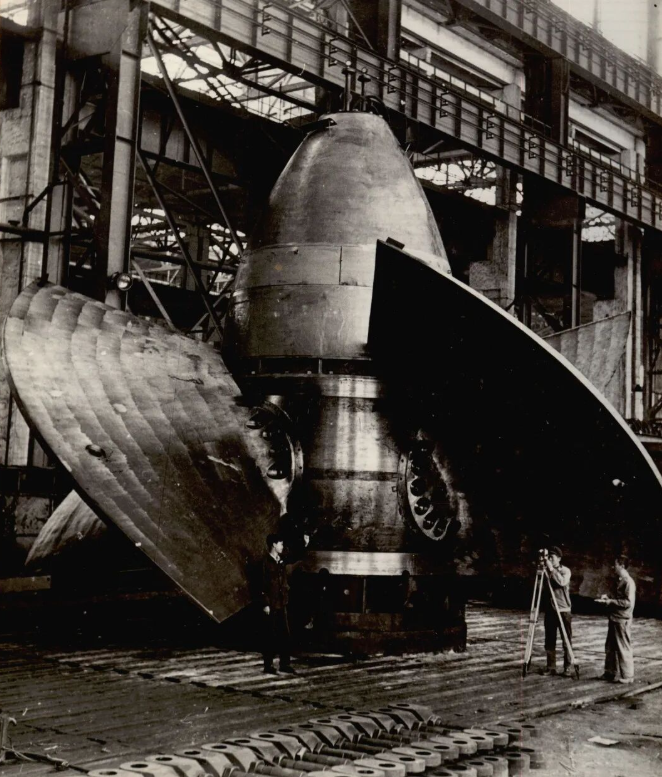

In December 2020, Dongfang Electric successfully built the intelligent, high-precision DF-300 impact hydraulic test platform, which passed expert acceptance smoothly. With this, Dongfang Electric gained the capability to conduct hydraulic tests on impact-type hydropower generators according to national regulations and standards. The 150 MW large impact turbine, independently developed by Dongfang Electric, weighs around 20 tons and has a maximum diameter of about 4 meters. It has been installed and applied at the Jinwo Hydropower Station in the Tianwan River Basin, Ya’an City, Sichuan Province, equipping China’s largest single-unit impact hydropower generator with a “Chinese heart.”

The impact turbine at the Jinwo Hydropower Station faces the continuous impact of high-speed, sediment-laden water jets during operation, which presents a series of complex challenges for turbine development. Despite facing this unprecedented challenge, Liang Quanwei insisted on setting four key goals for the R&D team. These goals were to ensure that Dongfang Electric’s turbine would not fall short in performance, output, reliability, and process feasibility when compared to the design plan provided by foreign companies to Sichuan Investment Group. During this period, Dongfang Electric’s R&D center meeting room was often filled with professionals from hydraulics, strength, structure, process, quality control, and other fields, discussing and debating various issues. The team developed over 80 design proposals for the impact turbine.

The results from testing these designs showed that Dongfang Electric’s turbine outperformed the foreign turbine in terms of hydraulic performance, which greatly excited the entire team. However, just when everyone thought they could relax, the structural design feedback came in: the stiffness still didn’t meet the requirements. Everyone agreed that a redesign was inevitable. This was a difficult decision because the previous 80+ design proposals had already taken six months, and now they had to complete a redesign and testing within just a month. Time was critical.

After repeated testing and analysis, the R&D team finally selected the optimal design that met all four goals. After validating and analyzing over 100 proposals, the team ensured that the turbine’s cyclic fatigue life would not be less than 1.5 billion cycles, and it could withstand impacts of 110-220 tons for 1.5 billion cycles. They successfully solved the structural design challenges for large impact turbines, ensuring both excellent turbine performance and structural reliability.

“From Gezhouba to the Three Gorges, from Xiluodu to Baihetan, after so many years of technological accumulation, we have the confidence that we can make impact hydropower generators well,” said Liang Quanwei.

At the end of May 1958, one evening, a train traveling from Baoji to Chengdu stopped at the Deyang Station in Sichuan. Nine people stepped off the train. They were the first group of pioneers who responded to the national “Third Front Construction” policy, coming from Harbin Electric Machinery Factory to support and help establish the Deyang Hydropower Equipment Factory, the predecessor of Dongfang Electric. On October 13th of that year, the Deyang Hydropower Equipment Factory was officially established. Later, Dongfang Electric and Harbin Electric Machinery became the two main pillars of China’s hydropower equipment industry.

From 1977 to 1988, Dongfang Electric accomplished a task that shocked the world. In the 1970s, the country began constructing the Gezhouba Hydropower Station project. At that time, Dongfang Electric proposed to develop a 170,000-kilowatt water turbine generator for Gezhouba. Such a large-scale water turbine generator had no precedent in the world at that time. During a design discussion for the Gezhouba water turbine generator at the original Ministry of Machinery Industry, some experts tried to overturn Dongfang Electric’s “large machine” design, even claiming that “this will be a pile of scrap iron thrown into the Yangtze River.” With strong experimental and analysis data, Dongfang Electric representatives refuted these remarks at the discussion meeting and insisted on their “large machine” design. After 1,500 days and nights of repeated tests, in 1981, Dongfang Electric successfully commissioned two 170,000-kilowatt water turbine generators for Gezhouba.

In 1985, the 170,000-kilowatt water turbine generators developed by Dongfang Electric for Gezhouba, alongside other major projects like the atomic bomb, hydrogen bomb, and Long March 3 rocket, were awarded the “State Scientific and Technological Progress Special Award”—the first such award in China’s hydropower history. According to Zhao Yongzhi, the Gezhouba project was one of the highest honors for Dongfang Electric, while the Three Gorges project marked a critical milestone in the company’s development history.

In 1996, the country established the international procurement rules for the Three Gorges project. Through a “bundled bidding” process, a model of “technology transfer — digestion and absorption — independent innovation” was adopted to build the Three Gorges hydropower units. Eventually, two major consortiums, including the French-Alstom-Swiss ABB joint venture, German Voith, and GE Canada, won the bid for the 14 units on the left bank of the Three Gorges. Dongfang Electric, as a domestic subcontractor, was tasked with manufacturing two of the generators for the left bank. At that time, the Three Gorges Group funded the dispatch of four of Dongfang Electric’s technical staff to GE Canada, Voith Germany, and Siemens to learn hydropower technology. Upon their return, the first thing they said to Zhao Yongzhi was, “We are at least 30 years behind foreign companies.”

From that moment on, Dongfang Electric deeply realized the importance of mastering core technologies independently. As a result, Dongfang Electric began organizing hydropower research teams, designing and constructing test platforms, and focusing on core technology development. After the left bank generators began operation, Dongfang Electric, which was learning and independently developing core technologies, seized a critical opportunity. At the time, only 36 years old, Shi Qinghua, one of the four technical staff sent to Canada for hydropower training, volunteered for the task. Starting with a subcontract from foreign companies for part of the Three Gorges Left Bank contract, Dongfang Electric achieved the national strategy of “technology transfer — digestion and absorption — independent innovation” in just seven years.

As Zhao Yongzhi put it: “On the right bank of the Three Gorges, we left the ‘foreign crutches’ behind.”

After the Three Gorges, Dongfang Electric achieved another major success at the Xiluodu Hydropower Station, the second-largest in China and the third-largest in the world. From 2008 to 2013, Dongfang Electric successfully developed and produced 9 units of 770,000-kilowatt mixed-flow hydropower turbines for the Xiluodu Hydropower Station, ending the long-standing monopoly of foreign companies in the 200-250-meter head range for large mixed-flow hydropower turbines. This achievement marked the first time China’s hydropower equipment’s hydraulic parameters reached international standards.

With significant accomplishments in world-renowned hydropower projects such as Gezhouba, Three Gorges, and Xiluodu, Dongfang Electric gradually gained recognition in the international hydropower market. In 2008, the Zhenri Hydropower Station in Brazil, the world’s largest hydroelectric plant with through-flow turbines, became another milestone. Zhao Yongzhi led the team to Lausanne, Switzerland, where Dongfang Electric competed with global hydropower giants like GE, Alstom, and Voith, winning an order for 22 units of 75,000-kilowatt through-flow turbines for the Zhenri Hydropower Station in Brazil. After numerous rounds of rigorous design, processing, and testing, Dongfang Electric’s products received worldwide recognition. Zhao Yongzhi still recalls when the president of the World Hydropower Association, Awei Lan, shook his hand and said, “China, amazing!”