In the early years of China’s petroleum industry, refining technology lagged far behind that of developed nations. Yet amid these limitations, one man — Min Enze — devoted his life to exploration, innovation, and service to his country. Through relentless research and an unyielding spirit of scientific curiosity, he built a comprehensive catalytic science system that laid the foundation for China’s modern refining technology.

At a time when global competition was fierce and foreign technology was strictly blocked by embargoes, Min led his team to break through multiple technological barriers. He pioneered advanced catalytic processes that transformed China’s petrochemical industry from one of dependence into one of leadership, elevating the nation’s international standing almost overnight.

Far ahead of his time, Min also foresaw the coming global emphasis on environmental protection. He became one of China’s earliest advocates of green chemistry, developing a series of eco-friendly industrial processes that helped guide China’s chemical industry toward a green and low-carbon transformation — a new era of ecological harmony and efficient resource utilization.

Reflecting on his decades of scientific work, Min once summarized his lifelong mission in three parts:

“First, to meet the urgent needs of national defense and refineries;

second, to help petrochemical enterprises overcome difficulties;

and third, to engage in fundamental, strategic, and long-term scientific research.”

The four characters “national need ” were the guiding light that illuminated every step of Min Enze’s journey of innovation.

Born in Chengdu, Sichuan Province, in 1924, Min Enze showed a boundless enthusiasm for learning from an early age. In his youth, during the turbulent waves of China’s modern transformation, he made a decisive choice: to serve where his nation needed him most.

At that time, Sichuan, a major agricultural province, was desperate for talent in fertilizer production. Realizing this urgent need, Min switched his university major in his second year to chemical engineering, vowing to apply his knowledge to help his homeland.

In 1948, he went to the United States for further studies. But due to international tensions and the changing global political landscape, he found himself stranded abroad. By 1955, now holding a Ph.D. in chemistry and having started a family, Min made the difficult decision to return home. Despite many obstacles and the strained relations between China and the U.S., he resolutely traveled back via Hong Kong.

In those uncertain times, Chinese scientists returning from the West were viewed with suspicion — were they valuable experts or potential spies? Through the recommendation of a friend, Min was finally assigned to the Beijing Institute of Petroleum Refining, where he began a new chapter in catalyst research.

In the early 1960s, international politics shifted again. The Soviet Union abruptly cut off the supply of catalysts to China, plunging the country’s aviation gasoline production into crisis. Determined to secure technological independence, the Ministry of Petroleum Industry decided to build a domestic catalyst plant at the Lanzhou Refinery, appointing Min Enze as Deputy Chief Commander.

“I was deeply moved,” Min later recalled. “I never expected the country to place such trust in me.”

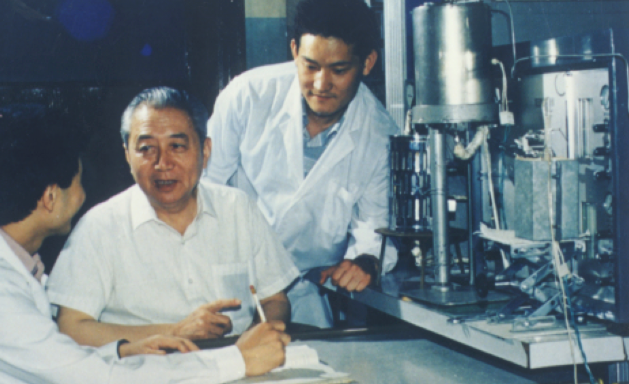

From plant design and process formulation to analytical testing and production control, Min took personal responsibility for nearly every technical issue during the construction phase. Balancing theory and practice, he studied, experimented, and summarized relentlessly. His work on the preparation of platinum reforming catalysts soon achieved remarkable progress.

When he realized that the existing foreign methods for producing aluminum oxide carriers did not suit China’s raw materials, he personally visited reagent factories in Beijing and Shandong to study their products’ characteristics. After countless trials, he developed a high-purity aluminum oxide production process tailored to China’s industrial conditions.

“Use your own legs,” he told his students, “and walk the path of your own investigation.”

By June 1958, the pilot-scale tests for the platinum reforming catalyst had succeeded. Min and his team had created a low-cost, high-purity aluminum oxide carrier, filling a critical technological gap in China’s petroleum industry.

During the pilot testing phase, Min’s home was located just across from the laboratory’s catalyst evaluation unit in Building No. 2. A small window connected his personal life and his scientific mission:

“At night, if I saw the lab lights still shining, I could sleep peacefully. But if the lights went out, it meant the catalyst had ‘died’. I couldn’t sleep the whole night — I’d rush to the lab first thing in the morning.”

For years, Min and his colleagues worked in cramped, rudimentary buildings, poring over foreign documents, searching for clues, and experimenting endlessly. Danger was routine; failure, a frequent companion. Yet each setback became a stepping stone toward success. Eventually, they overcame critical technical challenges such as high-temperature silicate processing in autoclaves.

When the Lanzhou Catalyst Plant was finally completed, it produced high-quality, low-cost catalysts that ensured the supply of aviation fuel for both military and civilian needs — a national triumph. But years of intense labor took their toll on Min’s health. After the “Lanzhou Campaign,” he developed lung cancer and underwent surgery to remove part of a lung and one rib.

By 1968, many of Min’s overseas classmates had reached the peaks of their careers. He, however, was carrying cement bags in manual labor, enduring political upheaval at home. Yet his faith never wavered.

“Returning from the U.S. 53 years ago,” he said in later years, “was the right choice. To dedicate my life to the construction of my country and to the needs of my people — that has been my greatest happiness.”

In 2005, at the age of 81, Min Enze received the First-Class National Award for Technological Invention for his groundbreaking work on amorphous alloy catalysts and magnetic stabilized-bed reaction processes. This technology, hailed as a “new weapon in petrochemistry,” was the fruit of over two decades of independent innovation.

Later, Min’s team successfully applied this new catalytic system to the hydrogenation refining of caprolactam, achieving the world’s first industrial-scale application of such technology. It significantly reduced operational costs, investment requirements, and energy consumption, while improving reaction efficiency — a milestone achievement in global chemical engineering.

Summarizing his innovative philosophy, Min outlined several principles:

Original innovation often comes from shifting the scientific foundation of existing technologies.Independent innovation includes three forms: original innovation, integrated innovation, and re-innovation through absorption.Innovation arises from association, and association comes from broad knowledge and collective wisdom.Spiritual strength — the sense of duty to one’s nation and people — is essential to overcome setbacks and persist to the end.

It was this spiritual power — a profound sense of national responsibility — that guided Min throughout his life.

In the 1990s, well into his seventies, Min redirected his focus toward green chemistry, dedicating himself to developing environmentally sustainable technologies. He led the creation of China’s unique green caprolactam process, which culminated in 2023 with the completion of the world’s largest and most advanced 600,000-ton-per-year caprolactam industrial facility — marking a monumental leap for China’s green chemical engineering.

Min Enze deeply valued teamwork. To him, scientific research was never about individual glory but about collective achievement.

On January 8, 2008, Min received China’s National Supreme Science and Technology Award. Standing before the nation, he humbly said:

“I am only the representative who went on stage to accept this honor. This award belongs to generations of petrochemical scientists whose collective wisdom made it possible.”

Many of Min’s students went on to become leading figures in China’s petrochemical research and academia. Despite his gentle temperament, Min was known for his uncompromising rigor. His former student Zong Baoning recalled:

“When I wrote my thesis, Mr. Min revised the structure and phrasing over and over again. My 20,000-word paper was rewritten seven or eight times by hand. Yet despite his strictness, working with him never felt tense — he allowed students to challenge him, to say ‘no,’ as long as their reasoning was sound. Even junior technicians could discuss ideas with him freely. That’s why so many young people loved working under him.”

In this open, respectful atmosphere, generations of scientists were nurtured — all guided by the same light that had illuminated Min Enze’s own life: the call of national need.